Restoration

October 26, 2001

The dry fall breeze ushers in the smell of burning leaves, rushing schools of mullet, and Leonard on his sailing skateboard. With creative geniouses like him on board, no wonder the Cherokee project is rolling right along. The crew has made a few preparations for winter. They took two hinged panels of the shed, raised them, and wrapped them in plastic to create two shed roofs one either side of the building. One is the sanding room, and the other is the paint room.

New and Improved Winterized Facility

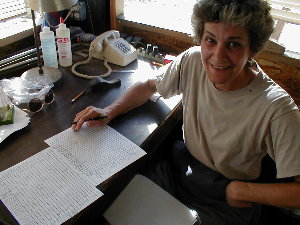

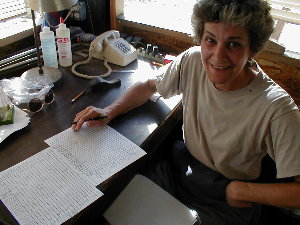

Bill Davis is shown below sanding the vessel foredeck in preparation for fiberglass. Jeanette, when not sanding, sawing, or gluing, has been working on a spread sheet for the project’s labor analysis. Good thing she wears that reversible white and blue collar.

Hitting the Deck and Doing the Books

The crew has been installing sound insulation in the engine room. It started in the Huckins boatyard fifty three years ago, when a three quarter inch plywood structural bulkhead was placed in the hull to separate the engine room from the rest of the boat. The Cherokee crew then built on that by gluing a three quarter inch piece of Divinicell to the quarter inch plywood bulkhead. The Divinicell is used to decouple the bulkhead from the engine room and cockpit area. Next came a layer of 1808 fiberglass cloth layed up with West System epoxy resin. To that, the crew glued a piece of quarter inch lead-impregnated vinyl dampening mat. This massive mat acts to absorb deeper vibrations by its sheer mass. One and a half by four inch stanchions were placed against this lead mat and are bolted into the engine stringers below. These stanchions are glued to the mat with a rubber adhesive (5200), and will support the cockpit deck. The areas between the two by four stanchions are filled with four inches of fiberglass batting. Next, quarter inch vinyl tough mat attaches, and then two and a half inches of additional wood framing encompass another two inch quilted batt of fiberglass. This all will be covered with a thin perforated aluminum sheet.

Bud and Insulating Matt

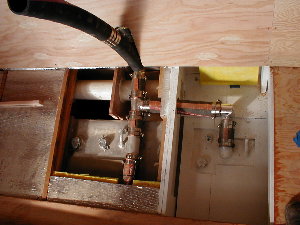

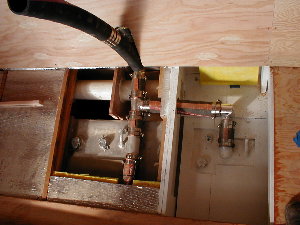

Leonard is permanently installing the water jets. He’s shown here placing nuts and bolts in the pockets. The pockets are then filled with expoxy resin with high density filler, encapsulating the nut and machine bolt. The machine bolt has been waxed so that it can be removed after the epoxy dries, making a threaded hole in the hull. This hole will be for the machine screws that hold the jets in place.

Leonard Installing Jets, Close Up of Bolt Pocket

Alien space pods multiplying in a hot zone? No – the picture below is of the Centiflex coupling, which will attach the water jets to the engines, freshly painted and drying. In the foreground is a newly painted oil pan. Pictured to the right is one of the air intakes along the side of the hull.

Paint Room Items, Air Intake Vent

Tom is building a plug that will cover the engine room emergency access hatch. The plug itself will be full of sound abating insulation as well.

Bryan and Tom Surveying the Plug

Norm, when not working on the engine room insulation, is installing fuel fill lines for the three diesel tanks. All fuel tanks are piped together so that they can be filled from either the port or starboard side. All in all, they will carry a grand total of 1,650 gallons.

Norm and the Fuel Line Project

Tom continues his work on the plumbing and head areas. He is installing the bathtub in master head, which looks way smaller here than actual size!

Tom Installing Master Head Bathtub

Leonard Land-Sailing his Break Away

The Marshallberg Volunteer Fire Department is abuzz with excitement because for the first time, they have the honor of hosting the Down East Christmas parade. The Christmas parade, full of scouts, fire trucks, church floats, and horses, brings together everyone from Cedar Island to Bettie. For all the unincorporated villages east of Beaufort, the fire departments are the only government entity, and are focal points for community gatherings and communication. Alton Chadwick is a charter member of the M’Berg VFD, signing up for Down East’s first fire department in 1954. “We had an old government oil tanker with an air-cooled motor and pump,” recalled Alton. “Later we converted an old Army truck – I made the body of her. We’d go clear to Atlantic with that old junk!” To raise money, the members collected one dollar from every household monthly. “I’d be shrimping all week, come in and then go door to door – Smyrna, Otway, Bettie, all over.” Alton is still on the scene after almost fifty years as a fire fighter. He’ll no doubt be on duty for the Christmas parade. “One time, the Queen was from Marshallberg and we were invited to be in Morehead City’s Christmas parade. I told their chief – you better at least put us second, because we got a pretty woman and a pretty truck!” Signing off for now, Barbara “Fish Doctor” Blake