Restoration

May 31, 2002

The end of May has a brought a mixed sky of towering thunderheads next to brilliant blue, as well as the smell of honeysuckle vines and varnish at the Cherokee site as the crew continues to work on the pretty interior work. Jeanette and Tom K. are varnishing the many drawer faces in this boat. Most of the drawers are built new, while some are original, and most are now varnished. Below are the results of Tom’s handiwork, hardening in the sun.

Varnished Drawers

Leonard has carved out the sea chest in the keel. The sea chest is not a secret place for gold and silver booty, but a box built inside the boat that fills with water. Several through-hulls can be located in one common area. Leonard is carving it to fit the perimeters required by the Kamewa water jets. The intake port for the engine is located ahead of the mufflers, several feet ahead of the allowable placement of the water intake on the exterior of the hull. This was accomplished by building a tunnel through the keel to allow water to travel through the opening located near the transom. The water will travel forward through the sea chest to the engine water intakes. The plate that Leonard is holding in place (below) constitutes the bottom of the sea chest. It can be removed to clean away debris and allow for anti-fouling paint to be applied each season.

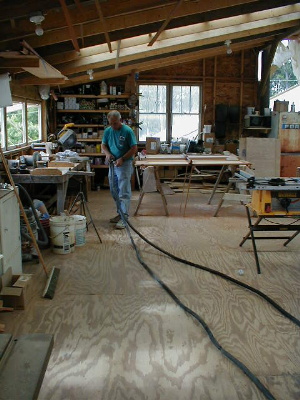

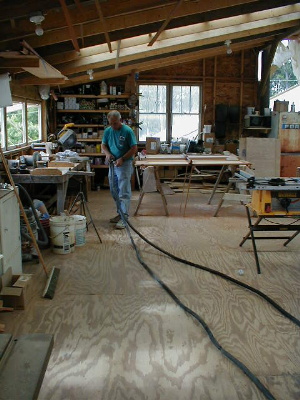

Leonard Building the Sea Chest

Captain’s Head Getting Fiberglassed

Wooden boats these days have their share of fiberglass. The particles are flying inside and out. Pictured above, the last head (showers, toilet, sink areas) is being fiberglassed. The underside of the hard top, below, has been coated in fiberglass and Kevlar. The next step for the hard top will be faring and painting.

Bottom of Hardtop with Kevlar and Fiberglass

Steve Gilpin is doing the tedious job of labeling and attaching all the negative legs of the wiring to the buss bars located on the wall within the electrical panel. Meanwhile, Bert the air-conditioning man (bottom right) is preparing one of the insulated copper-tubing runs that connect the compressors located in the equipment room to five different air handlers in various sections of the boat.

Buss Bars, A.C. Man

If all the words used to describe this restoration process were counted, which would show up most frequently? Sanding! Below Norm is shown sanding the white panels of the passage doors, and Jeanette is working on the trim which will go around all the cabinet doors. The trim will be sanded and varnished through its last coat before it’s cut and installed like picture frames around the already- painted white panels.

Norm and Jeanette Sanding and Trimming

Rail work is proceeding nicely. Below left is a varnished toe rail, and right is a picture of the rub rails that go on the aft quarter of the boat. Kerry is shown on the bottom sanding toe rails in preparation for a second layer of varnish.

Toe Rails and Rub Rails

Kerry Sanding Toe Rails

Fish Doc found Earl Chadwick reading the Bible in his porch swing this morning. “I’m just trying to settle my mind,” he said. Poor crab prices kept his pots out of the water this spring, and now he’s tending to his wife who has fallen ill. “I don’t like not working,” the 80-year old fisherman explained. Shrimp prices are low, too. “And they’ve been right small. But it’s usually good on the fifth night after a full moon on a flood tide.” Earl has spent his whole life on the water. He recalled serving on the U.S.S. Allentown during World War II off New Guinea and Japan and hearing Tokyo Rose taunting the American servicemen over the radio. “We had a time. Setting off those depth charges is what’s made me hard of hearing today! I was scared like everyone else,” he reflected, gazing out over the sleepy Marshallberg neighborhood that he’s lived in his entire life. “But you know what? I never had the feeling that I wasn’t coming home.” Signing off for now, Barbara “Fish Doctor” Blake